As a distributor of cream chargers nitrous oxide, their suppliers are all factories. Some factories seem to offer certificates, but there is no way to distinguish between good and bad quality, so they choose to buy nitrous oxide tanks at a low price, which is fine but may cause serious financial losses.

The Selection of the Materials In Nitrous Oxide Tanks

When choosing a supplier of cream chargers nitrous oxide, it is important that you pick a company that develops its products with the best quality materials. This includes the type of steel that is used to make the cylinders. But, which kind of steel is best for nitrous oxide tanks?

Manufacturers use different types of materials to house nitrous oxide, but the most common on the market are HP295 and Q235B. Our company always uses top-quality HP295 steel. Here are the main differences in quality between the two.

| HP295 | Q235B |

| ▪Acid washed ▪More expensive ▪Used with pickling ▪Cleaner and less prone to rust ▪Adapts well to temperature changes ▪The cylinder is less likely to burst under pressure ▪Top-quality, pure gas | ▪Not acid washed ▪Cheaper ▪Used without pickling ▪Not as clean and prone to rust ▪Doesn’t adapt well to temperature changes ▪The cylinder is more likely to burst under pressure ▪The purity of the gas may be compromised |

As you can see from this information, an HP295 cylinder is far superior to a Q235B cylinder. HP295 cylinders are more expensive to make, but they are made from a better material that will last longer and will not rupture when temperatures fluctuate in the kitchen. Nitrous oxide gas has a critical temperature of 36.5 degrees Celcius, and HP295 steel will not burst when it gets hot in the kitchen and the pressure inside the container increases.

HP295 steel cream chargers are also far more rust-resistant. This helps them to stay in the best condition for longer. It does not matter how humid it is in the kitchen, the cylinders will not be affected by rust. Because these containers are rust-proof, you can guarantee that you are getting a product that is clean and pure. The nitrous gas in our tanks is food grade and can be trusted.

When choosing a supplier of nitrous oxide cylinders, you want to make sure you get the best quality for your money. Here are some more differences between HP295 and Q235B steel that we’re sure will make you even more determined to purchase the right material.

| Type of Steel | Tensile Strength | Tensile Strength Yield |

| HP295 | 440-560 MPa | ≥295 MPa |

| Q235B | 370-550 MPa | ≥235 MPa |

As you can see from this information, suppliers that offer you nitrous oxide manufactured in HP295 steel are providing you with a better product. The tensile strength of this steel is higher. The higher tensile strength makes the material more durable and helps it to last under stressful environments without substituting its high performance. Q235B steel has low tensile strength and will not hold up as well in the ever-changing temperatures of the kitchen.

This information has also helped us to see that HP235 steel has a higher tensile strength yield. This again helps to increase the tension resistance and fatigue strength of the steel.

Is the wall thickness up to standard?

Another factor that you should be aware of when you purchase nitrous oxide cylinders is the thickness of the walls. According to the ISO1118 standard, the thickness of the tanks needs to be >2.3. Why? To avoid serious problems such as cracking, leaking, and exploding of the cream chargers.

Our cream chargers have a wall thickness of up to 2.5mm, giving you extra assurance that the material will not burst. Other manufacturers, however, like to get away with the bare minimum. Their nitrous oxide tanks’ walls are just 2.3mm thick, making them more prone to bursting.

So, what should you do? When choosing your food-grade nitrous oxide, make sure that the thickness of the material is up to standard. It should be at least 2.3mm but if it is a little thicker, such as 2.4mm or 2.5mm then that is even better.

Low-Pressure Nitrous Oxide Gas

Another factor that is important to consider when choosing E942 food-grade nitrous oxide is the pressure in the tank. Why is this so important? Well, if the pressure levels in the tank don’t hit the mark, you are likely to end up with a safety issue. This means that the cylinder could burst at any time and is more at risk of bursting when the nitrous oxygen is at a high temperature.

So, how do we make sure that our nitrous oxide tanks are as safe as possible? Here are three things that we strive to do:

- Our factory will only make tanks with the right amount of pressure. In fact, you can expect up to a 225bar from us whereas other manufacturers commonly make tanks with only 165bar. This eliminates the overpressure safety issues with filling nitrous oxide gas to 615g cream chargers.

- Our nitrous oxide cylinders are made with the right material, that is, HP295 which has higher tensile strength and yield than other materials on the market. This material makes the cylinders lighter in weight but without adding extra bulk. They are safer to use and instill our customers with confidence.

- The wall thickness of our products is up to 2.5mm. These extra thick walls make them more durable and more resistant to cracks and leaks.

Missing steel stamps on nitrous oxide cylinders

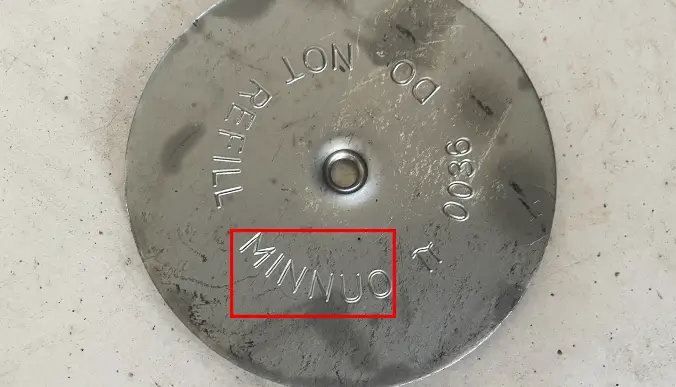

One more important feature is the company stamp. This stamp is key to helping the customer identify the manufacturer of the cylinder. A company should have its TUV stamp clearly labeled on each cylinder they sell. But many companies are reluctant to put their stamps on their nitrous oxide. Why is that?

Many big businesses spend all of their energy concentrating on the initial sale and do not have much or any aftercare services in place. Because of their lack of customer service, they are reluctant to put their factory stamp on the cylinders in case a customer should contact them with a problem.

It is not unusual for a nitrous oxide business to have very a limited customer crew that does not meet their client’s needs. They also use inferior products to build each nitrous oxide tank which makes them more susceptible to problems. Because a company like this cannot deliver the aftercare that a client will need, they do not put their contact information on their products.

But this is not the case with us. We Unicorncream(Minnuo group) make sure that our TUV stamp is on each nitrous oxide tank that we produce. Our team is here to help you place orders, go through the checkout process, shipping, and maintenance.

No testing performed

It is also essential that every nitrous oxide supplier performs tests on their stock. This will help them ensure that each tank is working the way it should and prevent customer complaints and disappointment. Unfortunately, many suppliers are so focused on the sale of each tank that they do not spend enough or any time at all testing them.

But that is not the case with us. We factory test each and every tank we sell. They go through rigorous tests before we deliver them to our clients. Here are some of the details of the tests that must take place.

- Factory test. Each tank is checked over that it is free from cracks, seams, laminations, or other defects. Its weld quality is also checked and we ensure it displays the proper markings.

- Airtightness test. Each tank is tested for leak detection.

- Burst test. This is where the cylinder is pressurised to test its pressure. It is tested at a rate of no more than 5 bar/min and the test pressure is maintained for 30 seconds.

- Hydro test. The cylinders are submerged under water or taken through other procedures to test their integrity.

Not Filling Up N2o Gas to 99.9995%

We also ensure that we give our customers what they pay for. So we make sure we fill our tanks with 99.995% of high-purity gas. This is something that we are very proud of as most companies only fill their tank 99.9% of the way. That extra bit of nitrous oxide per tank makes a big difference when you bulk buy.

We pride ourselves on producing nitrous oxide that is in top form for your health and that will guarantee a good time.

We have sold over 10 million nitrous oxide cylinders to consumers all over the world without any reports of breakage or customer complaints. So, if you are a distributor that is looking to stock up on a great deal, make sure you fill out the request form on our website. We are determined to ship your product on time and even provide you with the TUV third-party test certificate with your order.